Accel Digital Solutions, a 3D printing company based in Walker, Michigan, has created a quieter 3d printed pickleball designed to reduce noise levels and address complaints from residents near public courts.

The founders, Brandon Teets and Tyler Marvin engineered the ball to produce a softer, low-decibel “click” instead of the usual loud “pop.”

Due to noise concerns, some pickleball courts, including those in the Grand Rapids suburb of Walker, have faced closures. In response, Teets and Marvin developed a ball that aligns with USA Pickleball’s specifications for size, weight, pitch, and frequency, earning its certification for competitive play.

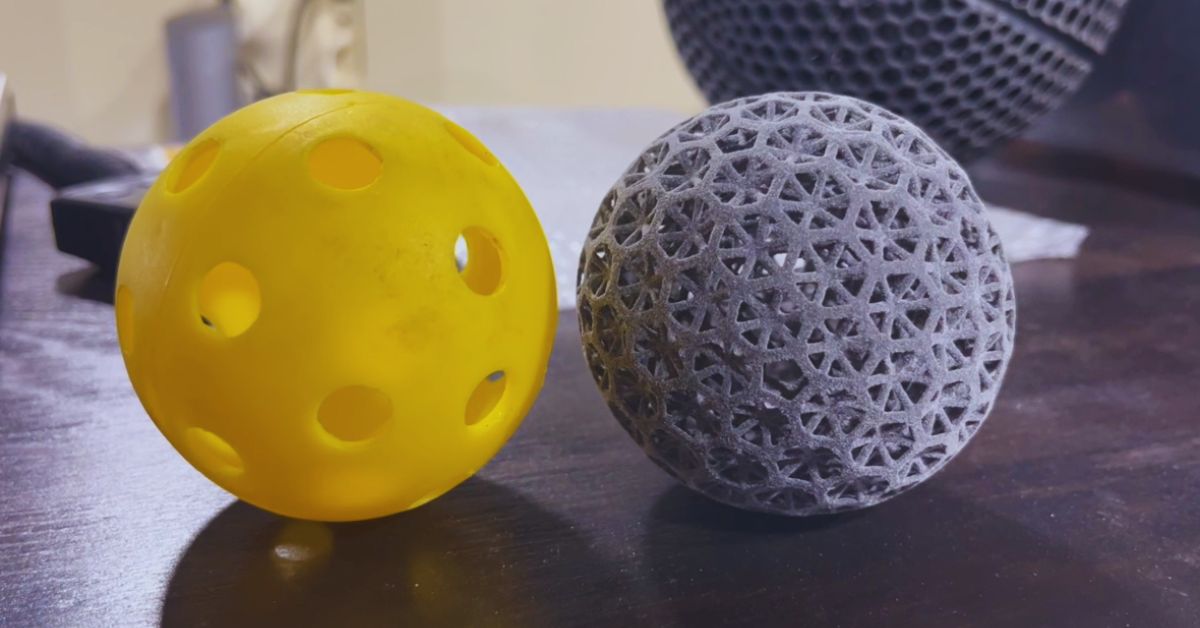

The ball, crafted through 3D printing using a thermoplastic elastomer, is designed to be softer and more flexible than conventional injection-molded or rotomolded pickleballs.

This innovative design significantly lowers the noise level. While still maintaining the necessary performance features.

Tests conducted by Pickleball Sound Mitigation showed that the ball emits a quieter “click,” resembling the “thump” of a tennis ball, while still providing sufficient feedback for players.

This new product, priced at $30 per ball, is currently available for purchase on the startup’s website. It targets recreational players and municipalities looking for effective noise reduction solutions for public courts.

Future versions will include a wider range of colors and ongoing improvements based on user feedback. Accel Digital Solutions is now accepting orders for this quiet pickleball on its website.